LobsterLift

The Problem

North Atlantic Right Whales (NARW) are facing extinction largely because they get entangled in fishing gear, including lobster trap lines. These lines, which connect a buoy at the surface to traps hundreds of feet down on the seafloor, are so long that whales swimming through get caught. The NARW population has only 500 members remaining worldwide [1], 4.3 of whom die annually on average [2], and an estimated 83% of whom have experienced entanglement [3]. Entanglement not only kills whales, but also renders female survivors less likely to reproduce; calving rates have dropped by 40% since 2010, and there is concern the species may not recover [2]. There is clear evidence that lobster traps have a significant impact on the NARW population: 80% of NARW entanglements over 30 years have been due to non-mobile pots and nets [3]. New England is both a lobster fishing mecca and one of the right whale’s primary habitats. If we are going to avoid the extinction of the NARWs, the industry urgently needs a solution that fishermen, regulators, and conservationists can agree on. More broadly, marine debris entanglements affect more than 200 species worldwide, with the majority of pinniped and cetacean entanglements resulting from encounters with actively fished gear, like lobster traps [4]. A solution to the problem of NARW entanglements in New England would inform scaled development to prevent whale-entanglement worldwide. * References available upon request.

Our Proposal

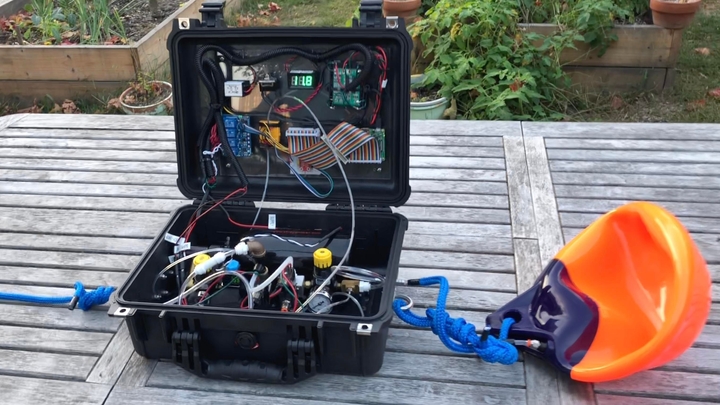

LobsterLift is a lineless, self-surfacing, modular lobster trap retrieval system. Traps utilizing LobsterLift sit entirely on the seafloor without requiring a line to the surface, and are raised when needed, thus eliminating the danger of whale entanglement. To retrieve a trawl (set of traps), a fisherman sends an acoustic signal from a tracker on the boat to a module attached to the trawl. The module then releases air from a tank to inflate an attached balloon. The balloon increases in size until it can float the trawl to the surface where the traps are retrieved, removed of their catch, and re-baited. In addition to helping to protect the endangered NARW, the LobsterLift provides several other benefits compared to existing techniques. The tracker on the boat can gauge signal strength from the module to triangulate its specific location. Locations plotted on a mobile application allow fishermen to recover their traps more easily than with line-based techniques. The LobsterLift also will aid regulators in optimizing use of marine resources while preventing overfishing. Because LobsterLift is location-aware, it can generate a real-time map of current trawls. This ensures that fishermen can maintain their fishing territories without physical markers, which enables them to continue self-regulating and can also be a monitoring tool for regulatory authorities.

We Assume that...

We assume that the device can be engineered so that false positives for inflation triggers are near impossible. This amounts to rigorous testing and good software engineering.

We assume that docking the module will not be burdensome. This is reasonable because it only adds a few seconds to the fishing process.

We assume that hydrophones are expensive because they are niche items with few producers + making our own will significantly reduce costs. This seems reasonable because its parts are not extravagant.

We assume that the onboard tracker will be able to reliably communicate with underwater modules. This is reasonable because there is abundant precedent for such technology (eg, raising mooring buoys).

Constraints to Overcome

Cost is perhaps the most important barrier to adoption of lineless trap retrieval systems. Other systems with similar solutions have been prototyped at near $20,000 per unit, with the only commercial system still costing an exorbitant $1000. For comparison, a lobster trap costs roughly $80. For a conservation-motivated solution to be widely adopted by fishermen, it needs to make financial sense. So far, no lineless system has been cost-effective. By lowering costs and adding features, we hope to make adopting LobsterLift a profitable business decision. Another critical barrier to adoption has been usability. The most readily available lineless system on the market today operates via a fusible metal link. To prepare this system for reuse, a fishermen must cut a short length of an exotic metal wire (typically a nickel-chromium alloy) and painstakingly install it between two terminals on the device. LobsterLift, on the other hand, is designed to be exceptionally simple to reuse.

Current Work

Over the next 3-6 months, we will be continuing to develop our prototype in conjunction with our collaboration with the lobster fishing industry. We are working with industry management in the Massachusetts area, as well as fishermen based in New Hampshire and Maine. Prototype: Reduce parts of system to be as minimal as possible Test operation of inflation through manual triggering via the computer system Preliminary research into development of the acoustic communications system needed to create a cost effective device Collaboration: Attend the Maine Fishermen’s Forum in Rockland, ME to better understand customer needs, and potential collaboration with fishermen and NOAA leadership at event Continue to work with team working on standardizing test method for all ropeless gear

Current Needs

We are looking for funding to help purchase equipment and materials necessary for the continued development of the functional prototype. We will need access to a boat, diving equipment, and other monitoring equipment for testing the functional performance of the prototypes and subsystems we develop. We would be connecting with local fishermen and local interest groups to have continuous feedback that the solution we are developing will have a strong chance of adoption by the community. We are also interested in connecting with any local interest groups that could subsidize the cost of a LobsterLift device for Maine fishermen. We would also like to connect with an underwater acoustics communication expert, because we understand that the dynamics of underwater communication are complex, and this is a critical element in our design.